Importance of Cooling in the Injection Molding Process

Introduction

The stage of cooling is an essential part of injection molding. Most individuals emphasize the injection and clamping processes but cooling may equally affect the quality of products. Cooling enhances the strength of parts, decreases the cycle time when performed properly and minimises the production costs.

This paper discusses the significance of coolers and the effect it has on all other sections of it. The process of pouring molten plastic into a mold is just a beginning. The plastic should also start solidifying properly before it is ejected. In the event of excessively fast or slow cooling, defects may arise.

These are warping, sinks and stresses within. Knowledge of cooling processes aids in better choices of the manufacturers on the design of the molds, material selection, and setting of manufactures. Now, we shall discuss the importance of cooling in some major headings.

The Role of Cooling in Injection Molding

The molten material is allowed into the mold and then cooling is done. This is the stage through which plastic cools off and is solidified. This process may appear to be a very easy step, yet its effect is enormous on the finished product.

In case the cooling system is not efficient, parts might deform or require too much time to be produced. This is the reason why the companies oriented to Mold Making and Injection Molding Solution – GBM pay great attention to the exact design of cooling.

Proper cooling means that parts do contract evenly, they have tight tolerances; they have the strength they require to be used.

How Cooling Affects Product Quality

Cooling has many implications on the quality of the products:

- Dimensional Accuracy: The unequal cooling leads to the shrinking of parts in different locations. This causes warpage and components which cannot fit well during assemblies.

- Surface Finish: The slow rate of cooling can result in a bad surface texture. Rapid cooling in the improper locations may bring about strains and scars on the surface.

- Internal Stress Levels: In case some areas become colder than others, internal stresses are created. These loads may cause fatigue to the part and decrease its working life.

- Crystallinity: In the case of the semicrystalline, the rate of cooling influences the structure of the final material. Excessively rapid cooling can provide weak crystalline areas.

These factors are balanced by good cooling design. It provides even heat extraction to the molding cavity.

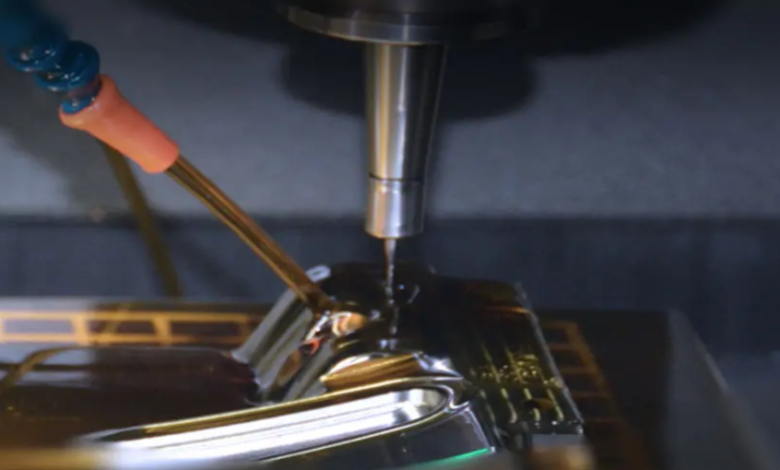

Cooling Channel Design and Placement

Effective cooling depends on how channels in the mold are designed. These channels are filled with a cooling medium, usually water, and run over the entire base of the mold. Their design must consider:

- Channel distance from cavity surface

- Channel size and shape

- Flow rate of cooling fluid

- Temperature control

When channels are too distant to the cavity surface, the removal of heat is slow. When they are too near they can make the tool weak or can lead to leakage. Complex geometries can be matched with spiral or conformal cooling channels.

This assists in uniform cooling of parts unlike straight-line channels. The software of modern simulation assists designers to experiment with the various layouts of cooling in order to develop the mold. This minimizes trial and error and minimizes the development time.

Cooling Materials and Thermal Conductivity

The cooling efficiency is not only determined by the design of the channels but also the materials to be used. Different alloys such as mold steel and aluminum possess varying thermal properties.

- Aluminum molds cool quicker than steel due to the fact that conduction of heat is better in aluminum. This can reduce cycle time.

- Hardened steel molds are better to wear off, yet not so quick to cool. The manufacturers have to strike a balance between the performance of cooling and the life of the tools and the volume of production that can be expected.

In other situations, inserts of high conductivity are installed in the vicinity of sensitive spots. These assist in extracting heat at a faster rate and leaving the rest of the mold sturdy.

Cooling System Controls and Regulation

Injection molding machines today are frequently equipped with sophisticated cooling systems so that the temperature of the equipment can be accurately kept constant over the molding cycle. Such controls accomplish a number of things:

- Monitor coolant temperature

- Adjust flow rates

- Manage multiple cooling circuits

- Respond to feedback from sensors

Temperature is also significant as plastic behavior varies with temperature. As an illustration, a couple of degrees of variation can alter the rate of shrinkage or flow patterns.

The operators need to install cooling controls depending on the material and the design of the part. It is easier to repeat conditions in the automated systems between cycles. It enhances consistency, which leads to quality and less scrap.

Common Cooling Problems and Solutions

Typically, despite a good design, problems are possible. These are some of the typical problems and solutions:

- Hot Spots: The places where the heat cannot be easily taken away. Problem-Solution: Addition of additional cooling channels or enhanced flow around that area.

- Uneven Cooling: There are places which cool more rapidly than others. Solution: Change channel location or counteract flow resistance.

- Flow Blockages: Scale or sediment in the cooling lines will diminish flow. Remedy: Cleaning and water treatment on a regular basis.

- Inconsistent Temperature: Thermal variations in coolant temperature have quality implications. Action plan: chillers or temperature control units.

Many failures of the cooling system can be avoided with the help of regular maintenance. Monitoring the performance of the pumps and the quality of fluids helps to extend the life of the mold and machine as well.

Bottom Line

Effective injection molding requires cooling. It affects the quality of parts, cycle time and costs of production. To produce any kind of toy (a simple toy, or a high-precision component in the medical industry) proper cooling design and control are key factors.

Considering Mold Making and Injection Molding Solution – GBM or any other supplier, you need to pay attention to the way in which the company deals with the design of the cooling system and optimization. Cooled down mold produces better parts, high production, and reduced defects. The reward of spending time in cooling design is paid every cycle. In order to learn more, visit the official site.