what does slump mean in concrete

Introduction to What Does Slump Mean in Concrete

Concrete is one of the most fundamental materials in modern construction, what does slump mean in concrete and its quality and workability play a critical role in the success of any building project. The question what does slump mean in concrete refers to a key measure of the consistency or workability of fresh concrete. Slump indicates how fluid or stiff a concrete mix is, which directly affects its ease of placement, compaction, and eventual structural performance. For construction professionals, understanding what does slump mean in concrete is essential for ensuring that concrete mixes meet project specifications and provide the required strength and durability. The slump test has become a standard procedure in both field and laboratory settings to determine the practical characteristics of fresh concrete before it sets.

Importance of Slump in Concrete

Understanding what does slump mean in concrete is important because the slump value directly influences the handling and placement of concrete on construction sites. A concrete mix with a high slump is more fluid, which makes it easier to pour into complex forms and fill gaps around reinforcement bars. However, excessively high slump may indicate too much water in the mix, which can weaken the concrete after curing. Conversely, a low slump indicates a stiff, dry mix that is difficult to work with but generally results in higher strength. Knowing what does slump mean in concrete allows engineers and contractors to adjust water content, aggregates, and admixtures to achieve the proper balance between workability and strength.

The Concrete Slump Test Procedure

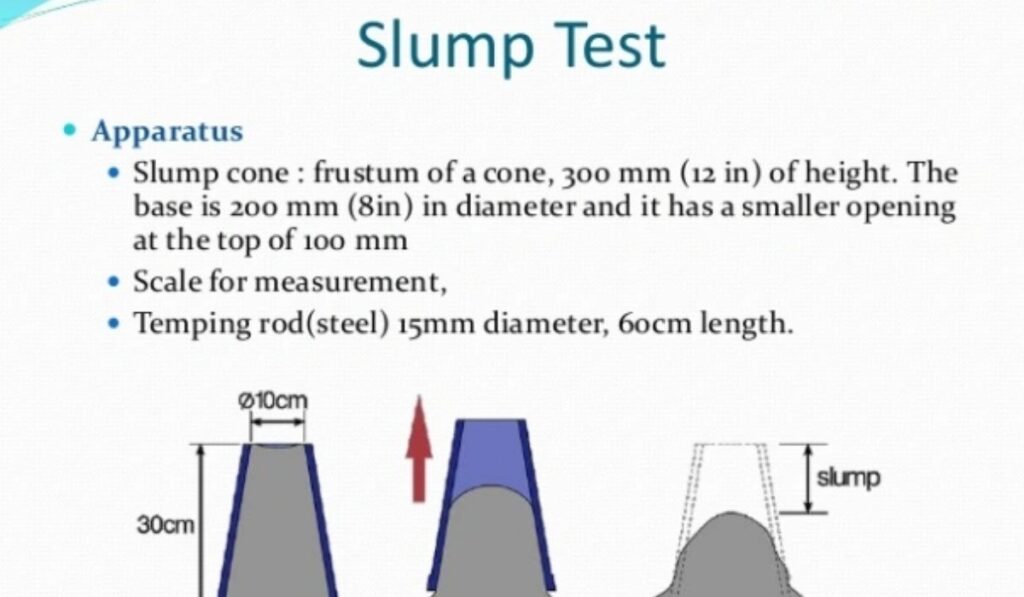

To explain what does slump mean in concrete, it is essential to discuss the test procedure. The slump test is performed using a standard metal mold called a slump cone, which is open at the top and bottom. Fresh concrete is poured into the cone in three layers, each tamped with a rod to remove air pockets. After the cone is lifted vertically, the concrete naturally slumps or settles under gravity. The difference between the height of the cone and the highest point of the slumped concrete is measured in millimeters or inches. This measurement represents the slump value, which is directly related to the concrete’s workability and fluidity.

Types of Slump Observed

Slump tests reveal three main types of slump behavior, which help answer the question what does slump mean in concrete in practical terms. True slump occurs when the concrete subsides evenly without collapsing. Shear slump occurs when part of the concrete shears off, indicating potential instability or mix imbalance. Collapse slump happens when the concrete completely loses shape, suggesting an overly wet mix. Recognizing the type of slump is crucial for adjusting concrete mixes and understanding how what does slump mean in concrete translates into real-world performance on construction sites.

Factors Affecting Slump

Several factors influence the value and type of slump, which further clarifies what does slump mean in concrete. Key factors include the water-cement ratio, aggregate size and shape, admixtures, and the mixing process. Higher water content generally increases slump, improving workability but potentially reducing final strength. Angular or rough-textured aggregates decrease slump, producing a stiffer mix. Chemical admixtures, such as superplasticizers, can increase slump without additional water, improving workability while maintaining strength. Understanding these factors allows construction professionals to manipulate what does slump mean in concrete according to project requirements.

Practical Applications of Slump Information

The practical applications of understanding what does slump mean in concrete are extensive. Slump values guide engineers and site managers in selecting the appropriate concrete mix for specific construction elements, such as slabs, beams, or columns. Proper slump ensures that concrete flows adequately around reinforcement bars, fills forms completely, and compacts correctly without voids. It also helps avoid issues like segregation, bleeding, or excessive shrinkage, which can compromise structural integrity. By interpreting what does slump mean in concrete accurately, construction teams can ensure both ease of placement and durability of the finished structure.

Standards and Guidelines

To standardize the interpretation of what does slump mean in concrete, several organizations provide guidelines, including ASTM, ACI, and local building codes. ASTM C143 outlines the procedure for measuring slump and provides criteria for acceptable slump ranges for different types of construction. ACI guidelines suggest slump values tailored to specific structural components and work environments. These standards ensure that all professionals have a common understanding of what does slump mean in concrete, facilitating consistent quality and reliable performance across different projects.

Limitations of the Slump Test

While the slump test provides valuable insights, it has limitations that construction professionals should consider when evaluating what does slump mean in concrete. The test primarily measures consistency and workability but does not directly predict strength or durability. Variations in aggregate moisture, temperature, or compaction can affect slump results, and extremely high or low slump may require additional testing methods. Recognizing these limitations ensures that what does slump mean in concrete is interpreted correctly, and additional tests, such as air content or compressive strength tests, can be used for a comprehensive evaluation.

Adjusting Concrete Mix Based on Slump

Understanding what does slump mean in concrete allows engineers to make informed adjustments to the concrete mix. If slump is too low, water or admixtures can be added to improve workability without compromising strength. If slump is too high, additional cement or aggregates may be required to achieve the desired consistency. These adjustments are critical for ensuring that concrete performs as intended in both fresh and hardened states. Proper manipulation of what does slump mean in concrete ensures optimal placement, compaction, and final performance.

Summary of What Slump Reveals

In conclusion, the question what does slump mean in concrete encompasses more than just a numerical value. Slump indicates the concrete’s workability, fluidity, and suitability for specific construction tasks. It helps professionals gauge the ease of placement, potential for segregation, and overall handling characteristics. By combining slump testing with other evaluations, construction teams can ensure that concrete meets project requirements for strength, durability, and long-term performance. Understanding what does slump mean in concrete is a foundational element of modern construction practice.

Frequently Asked Questions

1. What does slump mean in concrete

• It measures the consistency or workability of fresh concrete, indicating how easily it can be placed and compacted.

2. How is the slump of concrete measured

• Using a slump cone, concrete is filled in layers, tamped, then the cone is lifted to measure the vertical settlement.

3. What are the types of slump observed

• True slump, shear slump, and collapse slump indicate different consistency and stability of the concrete mix.

4. What factors affect concrete slump

• Water content, aggregate size, admixtures, and mixing process all influence slump values.

5. Why is knowing slump important in construction

• Slump ensures proper workability, filling of forms, compaction, and prevents segregation or voids in the concrete.